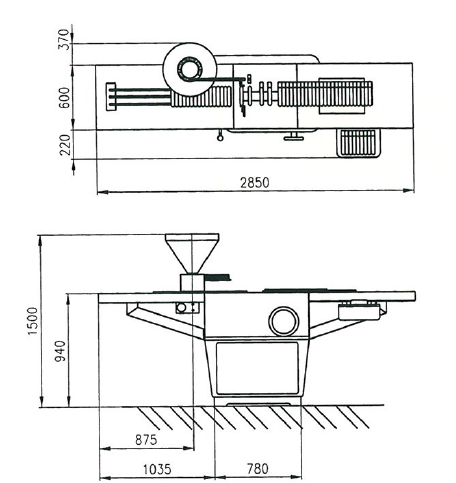

Introduction of the TP-100 / 160

The PMB TP-100 / 160 is one of the machines in the PMB 100 range. It can either be an independent unit or be synchronously coupled to a film wrapping machine (C-100), an ordinary or a rollband banding machine (S-100/R-100) and/or a cedar wood wrapping machine (W-100). Its speed is continuously adjustable up to an output of 120 cigars (or similar products ) per minute.

The PMB TP-100 / 160 is used for tipping, the first step in the finishing of cigars. The TP machines handles practically all common models of cigars and tips. To change the model of cigars or tips, adjustments to the machine are usually sufficient.

Distinctive for the PMB TP-100 / 160 are simplicity of design and dependability of operation. The tip hopper holds sufficient tips for about 1 hour's running. A vibrator conveyor is provided for feeding the tips to the fitting station, where glue is applied to the inner circumference of the tip before attachment to the cigar.

The cigars will have to be put down by hand or brought forward from a special feeder (e.g. type JL-100) onto the feedbelt of the machine. From there the product is moved individually to the fitting station, travelling sideways so that the wrapper is not damaged. Prior to and during tipping the cigar is held firmly while the relative location of the tip is adjusted before assembling. The glue application ensures a tight bond between cigar and tip, with no risk of exuding glue or "side leaks".